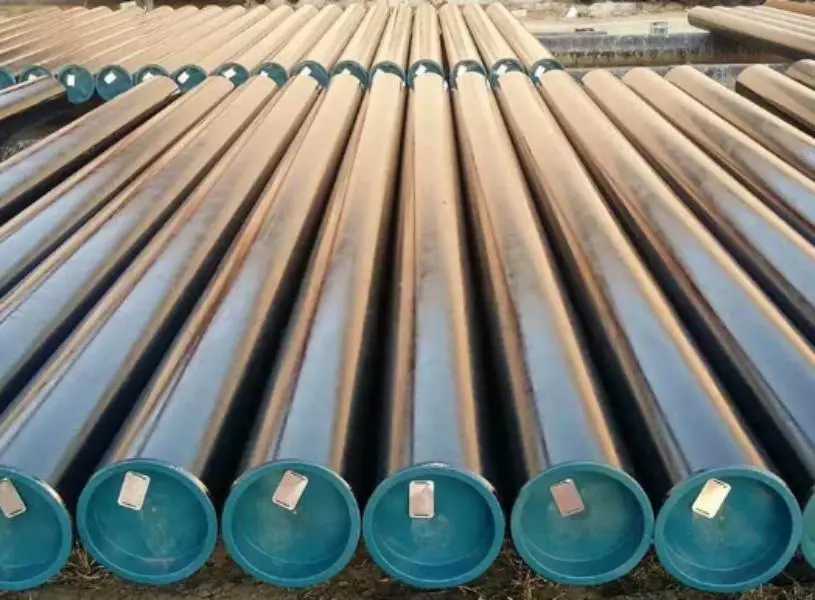

API 5L X42 steel pipe & API 5L X42 PSL2 Pipe have a high tensile strength, hardness and toughness to withstand fractures and cracks. The addition good weldability. Forming operations like flanging, welding or bending are well suited for X42 Pipe Material & API 5L X42 ERW Pipe.

| OD | 219-3220mm | |

| Size | Wall Thickness | 3-30mm SCH30,SCH40,STD,XS,SCH80,SCH160,XXS etc. |

| Length | 1-12m | |

| Steel material | Q195 → Grade B, SS330,SPHC, S185 Q215 → Grade C,CS Type B,SS330, SPHC Q235 → Grade D,SS400,S235JR,S235JO,S235J2 |

|

| Standard | JIS A5525, DIN 10208, ASTM A252, GB9711.1-1997 | |

| Usage | Used For Structure, Accessorize,Fluid Transportation And Construction | |

| Ends | Beveled | |

| End protector | 1) Plastic pipe cap 2)Iron protector |

|

| Surface Treatment | 1) Bared 2) Black Painted (varnish coating) 3) With Oiled 4) 3 PE, FBE |

|

| Technique | Electronic Resistance Welded (ERW ) Electronic Fusion Welded (EFW) Double Submerged Arc Welded (DSAW) |

|

| Type | Welded | |

| Welded Line Type | Spiral | |

| Inspection | With Hydraulic Testing, Eddy Current , Infrared Test | |

| Section Shape | Round | |

| Package | 1) Bundle, 2) In Bulk, 3) Clients’ Requirements |

|

| Delivery | 1) Container 2) Bulk carrier |

|

Ranges by Manufacturing Types

Seamless: Includes hot rolled seamless and cold drawn seamless, diameters up to 24 inch normally.

ERW: Electric Resistance Welded, OD up to 24 inch.

DSAW/SAW: Double Sub-merged Arck Welding, substitute welding methods than ERW for larger diameter welded pipes.

LSAW: Longitudinal Sub-merged Arc Welding, also called JCOE pipe, OD up to 56 inch. JCOE is named by manufacturing processes with J Shape, C shape, O shape and cold expanding process to release the pipe strength during transformations.

SSAW / HSAW: Spiral Sub-merged Arc Welding, or Helical SAW, diameters up to 100 inch

Technical data

Chemical Composition

| X42 PSL1 | X42 PSL2 | |||||||

| Grade | C (Max.) | Mn (Max.) | P (Max.) | S (Max.) | C (Max.) | Mn (Max.) | P (Max.) | S (Max.) |

| X42 | 0.26 | 1.30 | 0.03 | 0.03 | 0.22 | 1.40 | 0.025 | 0.015 |

Mechanical Properties

| Pipe Grade | Tensile Properties – X42 Pipe Body of SMLS and Welded Pipes PSL 2 | Seam of X42 Welded Pipe | |||||

| Yield Strength a | Tensile Strength a | Ratio a,c | Elongation | Tensile Strength d | |||

| Rt0,5 PSI Min | Rm PSI Min | R10,5IRm | (in 2in) | Rm (psi) | |||

| Af % | |||||||

| Minimum | Maximum | Minimum | Maximum | Maximum | Minimum | Minimum | |

| X42, X42R, X2Q, X42M | 42,100 | 71,800 | 60,200 | 95,000 | 0.93 | f | 60,200 |

Schedule Chart

| NB | DN | OD (mm) | API 5L X42 Pipe Schedule | |||||||||

| SCH 5 | SCH 10 | SCH 20 |

SCH 30 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 120 | SCH 160 | |||

| 3/4” | 20 | 26.67 | 1.65 | 2.11 | x | 2.41 | 2.87 | x | 3.91 | x | 4.32 | 5.56 |

| 1” | 25 | 33.40 | 1.65 | 2.77 | x | 2.90 | 3.38 | x | 4.55 | x | 5.08 | 6.35 |

| 1.1/2” | 40 | 48.26 | 1.65 | 2.77 | x | 3.18 | 3.68 | x | 5.08 | x | 5.72 | 7.14 |

| 2” | 50 | 60.32 | 1.65 | 2.77 | x | x | 3.91 | x | 5.54 | x | 6.35 | 8.74 |

| 2.1/2” | 65 | 73.02 | 2.11 | 3.05 | x | x | 5.16 | x | 7.01 | x | 7.62 | 9.53 |

| 3” | 80 | 88.9 | 2.11 | 3.05 | x | x | 5.49 | x | 7.62 | x | 8.89 | 11.13 |

| 4” | 100 | 114.3 | 2.11 | 3.05 | x | x | 6.02 | x | 8.56 | x | 11.10 | 13.49 |

| 5” | 125 | 141.3 | 5.77 | 3.4 | x | x | 6.55 | x | 9.53 | x | 12.70 | 15.88 |

| 6” | 150 | 168.27 | 2.77 | 3.4 | x | x | 7.11 | x | 10.97 | x | 14.27 | 18.26 |

| 8” | 200 | 219.07 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.7 | 12.70 | 15.06 | 18.24 | 23.01 |

| 10” | 250 | 273.05 | 3.4 | 4.19 | 6.35 | 7.8 | 9.27 | 12.7 | 15.06 | 18.24 | 21.41 | 28.58 |

| 12” | 300 | 323.85 | 4.19 | 4.57 | 6.35 | 8.38 | 10.31 | 12.7 | 17.45 | 21.41 | 25.40 | 33.32 |