Product introduction

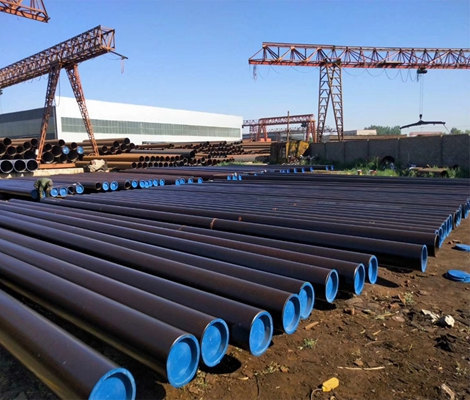

API 5CT K55 Casing Tubing serves to transport both crude oil and natural gas from oil and gas layer to the surface pipeline after drilling is completed. It is able to bear the pressure produced by the exploitation process. After the outer surface is coated with a protective layer, the tubing is marked in accordance with the API 5CT standard and strapped with metal belt.

API 5CT K55 Casing Tubing serves to transport both crude oil and natural gas from oil and gas layer to the surface pipeline after drilling is completed. It is able to bear the pressure produced by the exploitation process. After the outer surface is coated with a protective layer, the tubing is marked in accordance with the API 5CT standard and strapped with metal belt.

Our oilfield tubing & API 5CT K55 Casing Tubing can be widely applicable to petroleum, construction, shipbuilding, smelting, aviation, electric power, food, paper, chemical industry, medical equipment, boilers, heat exchangers, metallurgy and so on.

Specfications

| API 5CT K55 Seamless Casing pipe | |

| Available Sizes | 2 3/8″, 2 7/8″ and 3 ½” Outer Diameter |

| Grades | J55, J55-FBNAU, N80, L80, P110 |

| Tubing | 1 1/4 “ – 2 1/16” Nom. |

| Standards | API SPEC 5CT |

| Model in Common Use | 2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ |

| Length Range | R1(6.10-7.32m), R2(8.53-9.75m), R3(11.58-12.8m) |

| Steel Grade (Casing Grades, Tubing Grades) | J55, K55, N80-1, N80-Q, L80, P110 |

| Type of Screw Thread | Non upset threaded end(NUE), External upset threaded end(EUE) |

| Specialties | Coating to customer specifications

External upset Couplings – EUE, AB Modified, turned down, special clearance Pup Joints Heat treating Hydrostatic Testing Drifting (Full-length, or just ends) Full third-party inspection capabilities (EMI, SEA, and Weld Line) Threading |

| End Finishing | External Upset Ends (EUE), Flush Joint, PH6 (and equivalent connections), Integral Joint (IJ) |

Technical data

Chemical Composition

| Grade | Type | C | Mn | Mo | Cr | Ni max. | Cu max. | P max. | S max. | Si max. | ||||

| min. | max. | min. | max. | min. | max. | min. | max. | |||||||

| K55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – |

Mechanical Properties

| API 5CT Casing Standard | Type | API 5CT Casing Tensile Strength MPa |

API 5CT Casing Yield Strength MPa |

API 5CT Casing Hardness Max. |

| API SPEC 5CT | K55 | ≥517 | ≥655 | — |

Tensile & Hardness Requirement

| Grade | Type | Total elongation under load % | Yield strength MPa | Tensile strength min. MPa | Hardness a max. | Specified wall thickness mm |

Allowable hardness variation b HRC |

||

| min. | max . | HRC | HBW | ||||||

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | – | – |

K55 Casing pipe Dimensions

| Pipe Casing Sizes, Oilfield Casing Sizes & Casing Drift Sizes | |

| Outer Diameter (Casing Pipe Sizes) | 4 1/2″-20″, (114.3-508mm) |

| Standard Casing Sizes | 4 1/2″-20″, (114.3-508mm) |

| Thread Type | Buttress thread casing, Long round thread casing, Short round thread casing |

| Function | It can protect the tubing pipe. |