About the aluminum

6061 is a common duralumin with good machinability and moderate strength. 6061 is a heat-treatable alloy with good formability, weldability, machinability, and moderate strength. It can still maintain good operation after annealing.

The main alloying elements of 6061 alloy are magnesium and silicon, and form Ma2Si phase. If there is a certain amount of manganese and chromium, the bad effect of iron can be neutralized. Sometimes add a small amount of copper or zinc, in order to improve the strength of the alloy, and do not make its corrosion resistance has a significant reduction, there is a small amount of copper in the conductive material, to offset the bad effect of titanium and iron on electrical conductivity; Zirconium or titanium can refine grain and control recrystallization structure. Lead and bismuth are added to improve machinability. Mq2Si is solidly dissolved in aluminum, which makes the alloy have artificial age hardening function.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Thickness | 0.1-400mm,etc | Length: | 100-12000mm,or as required |

| Width | 20-3000mm,etc | Standard: | ASTM,AISI,JIS,GB, DIN,EN |

| Certification: | ISO, SGS,BV | ||

| Surface finish | mill,bright,polished,hair line,brush,sand Blast,checkered,embossed,etching,etc | ||

| Grade | 1000 Series: 1050 1060 1070 1100 1200 1235 etc. | ||

| 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. | |||

| 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. | |||

| 6000 Series: 6061 6063 6082 6A02 etc. | |||

| 7000 Series: 7050 7475 7075 etc. | |||

| Temper | H12,H14,H16,H18,H20,H22,H24,H26,H28,H32,H36,H38,HO,H111,H112,H114,H116,H118,H321. | ||

| Payment Terms | T/T, L/C at sight,West Union,D/P,D/A,Paypal | Loading port | any port in China |

| Packing | standard export packing (inside:water proof paper,outside:steel covered with strips and pallets) | ||

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) | ||

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) | |||

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) | |||

Product Detail

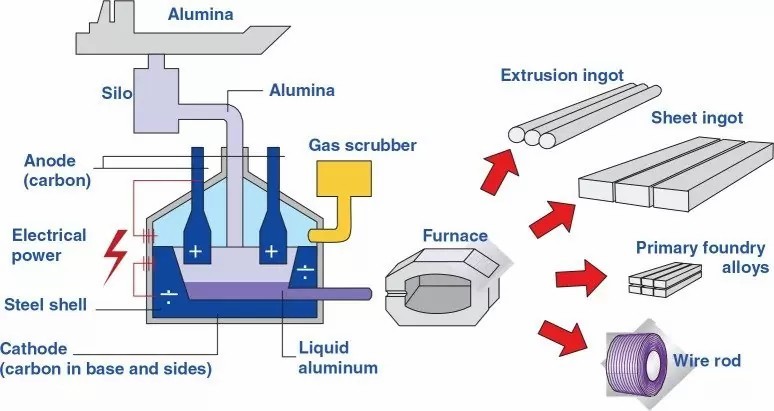

Aluminum Production Process

ADVANTAGE

Professional sales team,providing customers with first-class services;

Professional sales team,providing customers with first-class services;

Advanced scientific and technical team to improve production and reduce costs for customers

Intimate shipping logistics team protecting product transportation

COURSE

■ Roll casting

Aluminium ingot into quiet place furnace and vertical plate with casting machine, the thickness is 7.7 to 5.5 thick thick burrs, the 1060-1260-1360-1460-1560 and then transferred to the cold machine,, cold machine cutting quantity at least 3 cm,Casting of blank are generally burrs out, to the round edge, and then to the cold.

■ Cold rolling

Tied to the thickness we need, to 14 and 24, if it’s 24, annealing directly.

■ Annealing

Annealing time probably in 12 hours.

The winter air about 12 hours, air-cooled 18 to 20 hours of summer can only be air cooled through finished product.

■ Packaging

Customize the packaging according to customer’s requirements.

PACKAGING